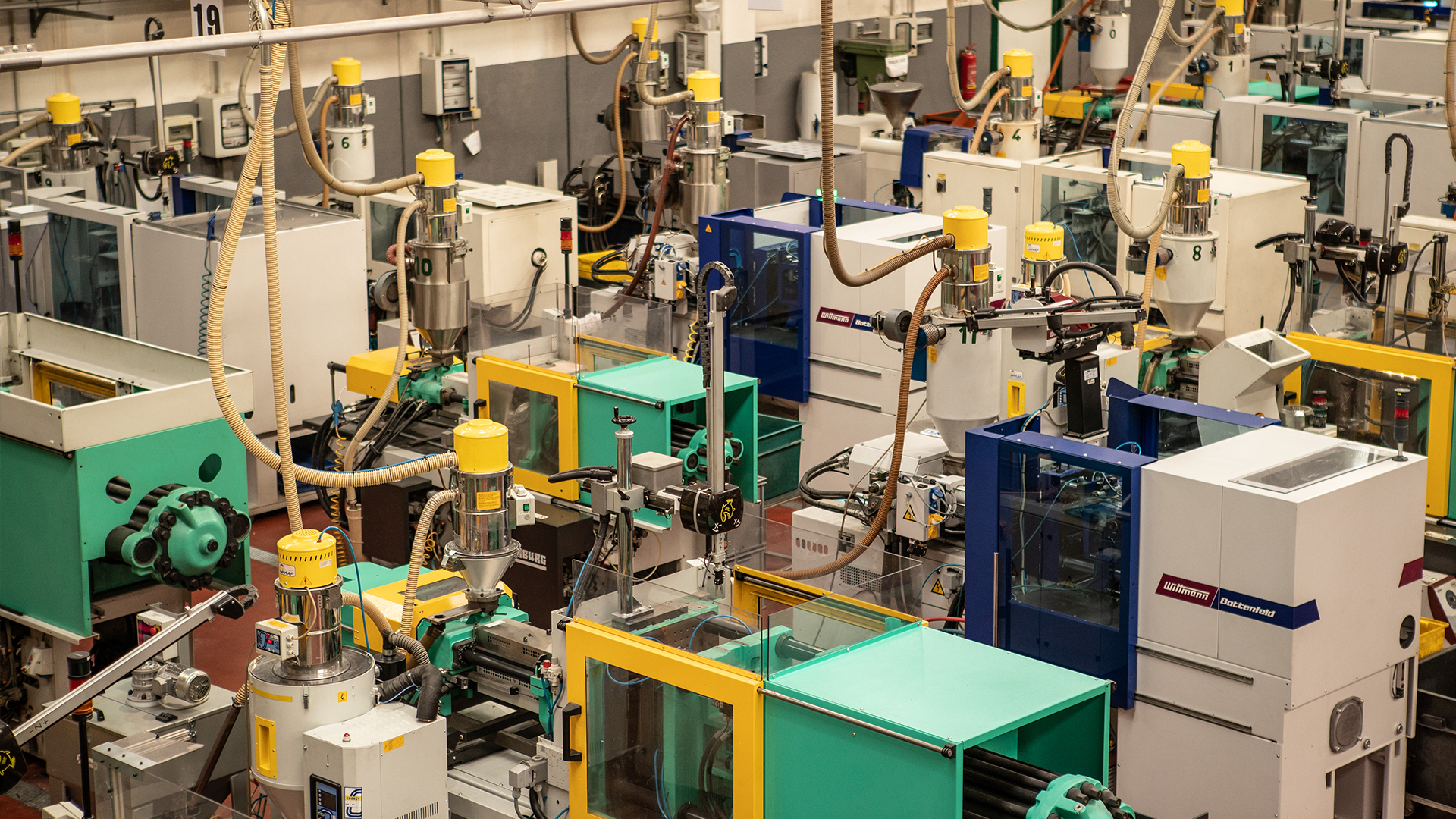

New Omap systems for superior added value moulding

New Omap machinery manages the mixing, transportation and preparation of a wide range of polymers, technopolymers, super polymers, metal replacements, and bioplastics – to name just a few. We design bespoke machinery for different applications – all tailored to meet the ever-more exacting needs of our clients. Machinery that’s built to last, and that’s capable of combining different requirements regarding materials, workability and the precise preparation of raw materials.

Our decades of experience partnering manufacturers and deep knowledge of their needs, combined with our extensive skill and experience acquired over many years are your assurance that you can rely on us to be your trusted partner. With the support of our team of experts, on hand both to identify the most suitable machine for the application and to provide impeccable after-sales service, those who choose New Omap know they can rely on systems that are traceable and safe over time.

Below are just a selection of the plastics our systems handle:

- polymethylpentene (or TPX), used in particular for producing articles for clinical laboratories. It's resistant to sterilization and perfectly transparent;

- polyamides, thermosetting resins that remain unaltered if subjected to temperatures of 300°C for extended periods, a property that makes them popular in the automotive industry for engine components as well as microwave ovens;

- acetal resins, polyphenylene oxide, ionomers, polysulfones, polyphenylene sulphide, and polybutylene terephthalate – the polycarbonate used to produce space helmets for astronauts, contact lenses, and bulletproof shields among other things.