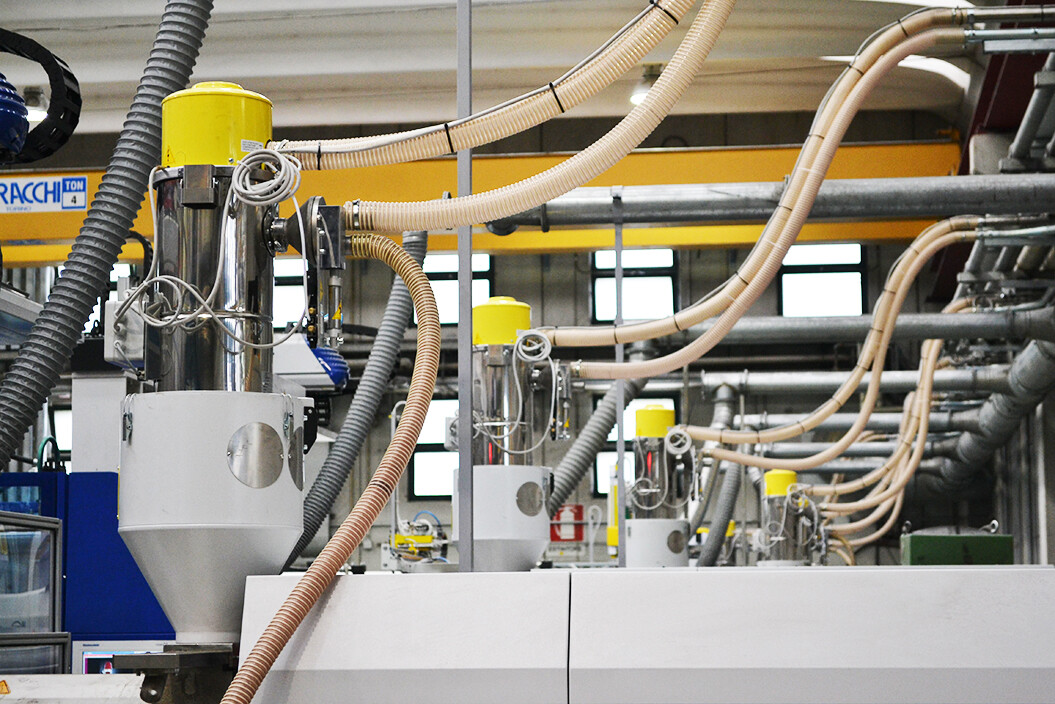

Central feeding systems

New Omap realizes centralized conveying and drying systems very versatile and with convenient modular features. Our conveying systems are pneumatic operated by vacuum and the control is functioning by sequential machine “call” - “starvation” method.

The brain of the system is the main microprocessor- based electronic card for the management of the whole system, which is receiving and transmitting all data required.

Its construction and design make it reliable and easy to use. It is fitted with serial outlet for connection to personal computer in case supervision system would be required.

The brain of the system is the main microprocessor- based electronic card for the management of the whole system, which is receiving and transmitting all data required.

Its construction and design make it reliable and easy to use. It is fitted with serial outlet for connection to personal computer in case supervision system would be required.

The microprocessor card can operate material receivers, vacuum blowers, pipe cleaning valves, silo selecting valves, proportional valves.

The control handles the peripherals by using 24 Vac, on a one cable only solution.

New Omap offers vacuum blowers with ranges of airflows and static pressures suitable to the requirements of the lay-out and type of installation.

The control handles the peripherals by using 24 Vac, on a one cable only solution.

New Omap offers vacuum blowers with ranges of airflows and static pressures suitable to the requirements of the lay-out and type of installation.

Blowers can be side channel, multi-stages, roots or claw type. Cyclone and bag filters of suitable dimensions and filtering degrees are completing the suction units for the protection of the blower and for the reduction of the circulation of dust in the system.

The available models are bag type for medium large capacity systems and cartridge filter for small capacity systems.

The available models are bag type for medium large capacity systems and cartridge filter for small capacity systems.

For dustier plants cyclone type FC filters have been designed.

The upgrade to the new type of control, allows the integration to the system of manifolds with decoding and fully automatic manifolds for a complete supervision and management of the material flow.

The implementation of the inverter will allow a dedicated speed setting of the granules, for each of the receivers, lowering considerably the wear and tear of the system and the amount of dust created.

The upgrade to the new type of control, allows the integration to the system of manifolds with decoding and fully automatic manifolds for a complete supervision and management of the material flow.

The implementation of the inverter will allow a dedicated speed setting of the granules, for each of the receivers, lowering considerably the wear and tear of the system and the amount of dust created.

CHS300T CENTRAL FEEDING SYSTEM

The typical solution of a pneumatic conveying system foresees: one vacuum blower, in most cases there is one backup pump in stand-by, and one main filter with automatic cleaning.

A pneumatic by-pass valve on the vacuum blower allows motor continuous operation. Pipe cleaning valves are suitable to purge pipe lines from material maintaining the lines free from stagnant material avoiding from risks of overloads for pipe clogging, discontinuous feeding and cooling of dehumidified materials.

For systems with material drying the models are selected to arrange closed loop lines to avoid the re-absorption of humidity of the material in the processing machine hopper.

New Omap proposes vacuum material receivers in stainless steel all endowed with dedicated electronic card for local parameters setting which is interactive with the main system control CHS300T.

The main control CHS300T handles material receivers and vacuum blowers, and operates according to the “starvation” method which operates by sequential priority with precedence of “call”.

CHS300T with a touchscreen type of interface and with its possibility to be connected to the internet, either via the company intranet or with direct connection to the network with cloud access via Nebula, it allows the export of all system data and also the possibility of remote control and service.

A pneumatic by-pass valve on the vacuum blower allows motor continuous operation. Pipe cleaning valves are suitable to purge pipe lines from material maintaining the lines free from stagnant material avoiding from risks of overloads for pipe clogging, discontinuous feeding and cooling of dehumidified materials.

For systems with material drying the models are selected to arrange closed loop lines to avoid the re-absorption of humidity of the material in the processing machine hopper.

New Omap proposes vacuum material receivers in stainless steel all endowed with dedicated electronic card for local parameters setting which is interactive with the main system control CHS300T.

The main control CHS300T handles material receivers and vacuum blowers, and operates according to the “starvation” method which operates by sequential priority with precedence of “call”.

CHS300T with a touchscreen type of interface and with its possibility to be connected to the internet, either via the company intranet or with direct connection to the network with cloud access via Nebula, it allows the export of all system data and also the possibility of remote control and service.

CORE-8 CENTRAL FEEDING SYSTEM

CORE-8 is a dedicated 8-stations material handling system, easy to install, easy to operate. The system is composed by a vacuum blower and a series of material receivers, up to max 8. Typical for installation on gravimetric blenders or for small feeding systems.

System conveying of plastic granules by vacuum feeding.

Vacuum blowers fitted also with FT, FMT or FSR filters depending on blower size.

Material receivers in different volumes, fitted with pneumatic vacuum-breaker valve and electronic box control with digit display and keypad for local parameters setting.

System conveying of plastic granules by vacuum feeding.

Vacuum blowers fitted also with FT, FMT or FSR filters depending on blower size.

Material receivers in different volumes, fitted with pneumatic vacuum-breaker valve and electronic box control with digit display and keypad for local parameters setting.

Vacuum blower

- Side-channel type

- From 0.85 to 11 kW

- Floor standing frame

- Electrical control box with main switch (no display nor keys)

- Filters FT, FMT, FSR

- From 0.85 to 11 kW

- Floor standing frame

- Electrical control box with main switch (no display nor keys)

- Filters FT, FMT, FSR

Receivers

All receivers are fitted with metal mesh filter, pneumatic “break-vacuum” valve for the connection to the vacuum line.

Pneumatic proportional ratio valves can be fitted to all the models of receivers.

The ratio valves have a special design with tangential closing with metal over- metal tightening, without gasket.

The ratio valves have a special design with tangential closing with metal over- metal tightening, without gasket.

Material receivers

- From 3 to 100 litres

- Stainless steel AISI304

- Pneumatic vacuum-breaker valve 24Vac

- Magnetic level sensor

- Mesh metal filter

- Slave control box with keypad for local parameters setting

- Alarm led

- From 3 to 100 litres

- Stainless steel AISI304

- Pneumatic vacuum-breaker valve 24Vac

- Magnetic level sensor

- Mesh metal filter

- Slave control box with keypad for local parameters setting

- Alarm led

Options

- Stand-by pumps

- Handy remote control with LCD display

- In-line cyclone filter

- Handy remote control with LCD display

- In-line cyclone filter