We constantly innovate and seek out new ideas. Because new ideas, technologies and methods to help us grow our business are emerging every day.

Our history

How we became New Omap

Looking back, New Omap was established even earlier than 1972. More precisely, it was when Adriano Brusamolin recognises the enormous potential of a developing sector – one he had firsthand experience in: the processing of plastics.

Since then, we’ve always considered our work to be a fascinating challenge – one that always encourages us give of our best. Starting from our very first single-phase hopper loader, we’ve gradually designed and developed increasingly innovative and above all functional products which deliver reliable efficiency and stand the test of time. Even today, our first New Omap machines are still going strong in the factories of our very first clients.

Since 1993, we’ve been running New Omap: we’re the second generation of the Brusamolin and Penello families, and we’re committed to making our machines perform even better and ensuring our company is your reliable and expert partner.

A recent example of our constant growth is the success of Nebula – our remote machine control system. And it’s this growth, coupled with our distribution network, new technologies, the attention we dedicate to each and every client, and the strength of our after-sales service, that has led to us becoming a business of recognized value in over 40 countries around the world.

A recent example of our constant growth is the success of Nebula – our remote machine control system. And it’s this growth, coupled with our distribution network, new technologies, the attention we dedicate to each and every client, and the strength of our after-sales service, that has led to us becoming a business of recognized value in over 40 countries around the world.

We’re dynamic

We're reliable

Time has forged our expertise. Challenges strengthen us. The future awaits us more determined. Reliability is our watchword.

We're responsible

Our machinery embodies our approach to work. An approach we’ve been applying since 1972: knowledgeable, safe and professional.

La nostra evoluzione

The key milestones

Our first ten years

1972 - Omap is established and production of the first single-phase hopper loader commences

1974 - launch of the first automatic centralised loading system

1980-1982 - development of our first water- and compressed air-free dryers, gasket-free proportional valve and gasket-free dryer shuttle valves

1974 - launch of the first automatic centralised loading system

1980-1982 - development of our first water- and compressed air-free dryers, gasket-free proportional valve and gasket-free dryer shuttle valves

The company evolves

1993 - Roberto and Romina Brusamolin and Vittorio and Nicola Penello take over the company and rename it New Omap

2000 - the company seals its first European partnerships

2007 - the company changes its corporate structure to become NEW OMAP srl

2000 - the company seals its first European partnerships

2007 - the company changes its corporate structure to become NEW OMAP srl

The product range is enlarged

2008-2012 - we design and manufacture new series of hot air dryers and dehumidifiers (the low-energy consumption DE series; the WD and WDS rotor honeycomb series; the AD and ADK compressed air series; with large air flow rates)

2012 - development of the new DV Volumetric Dosers series

2014 - establishment of New Omap’s first non-European partnerships

2016 - production of the first WD15-30 compact rotor dryers series starts

2012 - development of the new DV Volumetric Dosers series

2014 - establishment of New Omap’s first non-European partnerships

2016 - production of the first WD15-30 compact rotor dryers series starts

The company goes digital

2019 - the new Nebula cloud-based system is launched

2020 - New Omap becomes an Amaplast partner

2020 - centralized systems, volumetric dosing units and dryers are certified 4.0-ready

2020 - New Omap becomes an Amaplast partner

2020 - centralized systems, volumetric dosing units and dryers are certified 4.0-ready

Our method

Added value

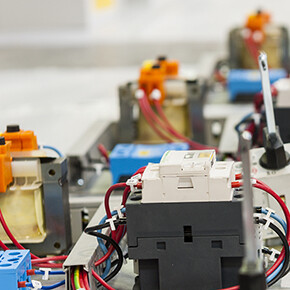

We select quality materials, use advanced technologies and still today we personally "get our hands dirty" each and every day. Because each machine that leaves our factory represents the professionalism and commitment that are our hallmarks.

And even after creating them, our extensive experience and technical solutions that we’ve constantly been honing over the years mean we’re on hand to intervene swiftly on our systems, to ensure they deliver efficient and reliable service – always.

We call it Hands-on Technology – the name that embodies the essence of our experience, reliability and dynamism.

And even after creating them, our extensive experience and technical solutions that we’ve constantly been honing over the years mean we’re on hand to intervene swiftly on our systems, to ensure they deliver efficient and reliable service – always.

We call it Hands-on Technology – the name that embodies the essence of our experience, reliability and dynamism.

Our presence

In the world